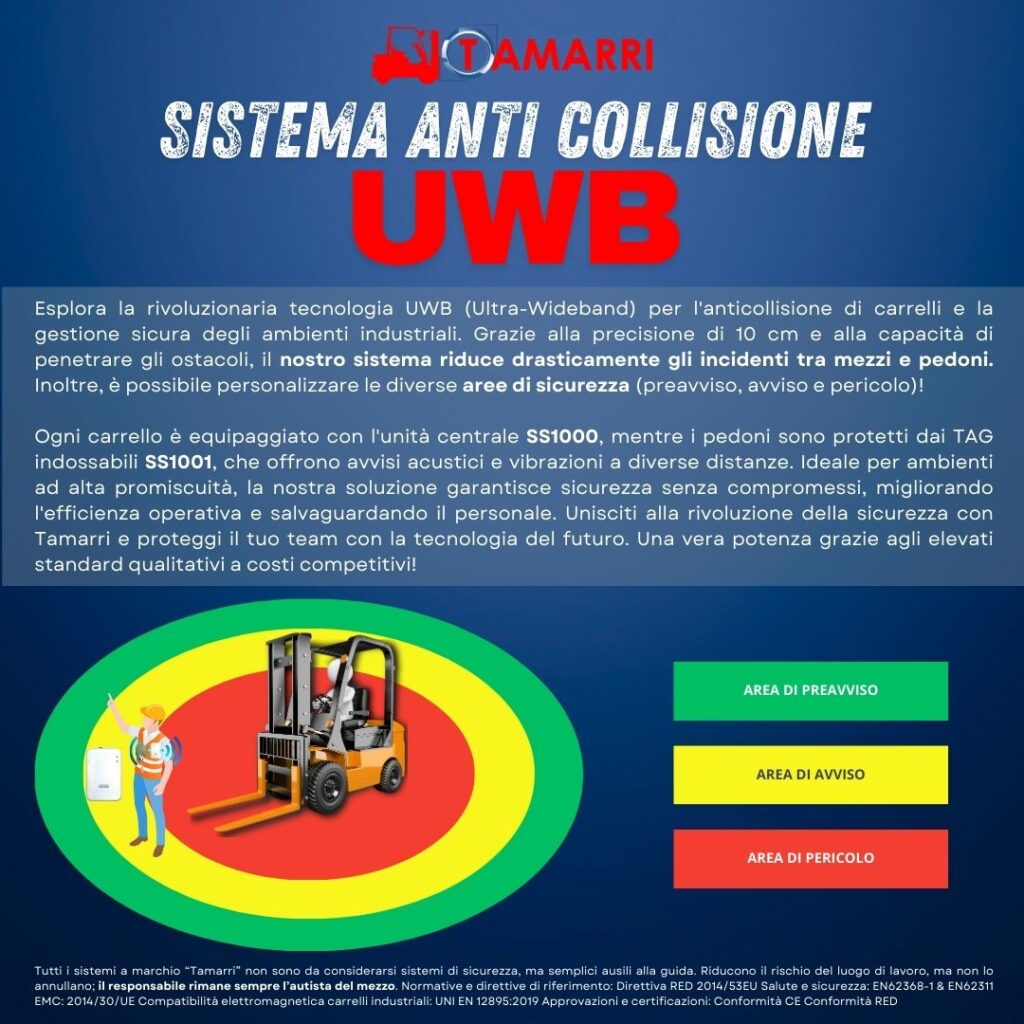

In the dynamic world of logistics and handling, safety is a top priority. Tamarri Srl, leader in the forklift spare parts sector, is proud to present the latest innovation in safety: the Anti-Collision System with Ultra Wide Band (UWB) technology.

The security revolution: UWB technology

The Tamarri Srl UWB System is designed to significantly improve safety in warehouses, construction sites and in work environments where forklifts and other industrial vehicles operate. UWB technology guarantees a detection precision of up to 10 cm, allowing you to identify obstacles and pedestrians through physical obstacles, with a minimal tendency to signal bounces. These characteristics make our system particularly effective in environments with high promiscuity of vehicles and pedestrians.

Main functions

The UWB System offers three main functions to ensure safety:

- Pedestrian-vehicle anti-collisionThis function detects the presence of pedestrians equipped with SS1001 wearable TAGs within four configurable safety areas. In case of danger, the system emits audible and visual alarms both on the main device SS1000 and on the wearable TAGs, alerting both the driver and pedestrians.

- Machine-to-machine collision preventionThanks to the SS1000 central unit, equipped vehicles can detect the presence of other vehicles nearby, reducing the risk of collisions in areas of poor visibility or at intersections.

- Management of intersections and work areasAlso known as zoning, this system slows down vehicles near intersections or limited areas, thanks to the use of SS1002 powered sensors, strategically positioned.

Pedestrian-vehicle anti-collision: safety at the highest levels

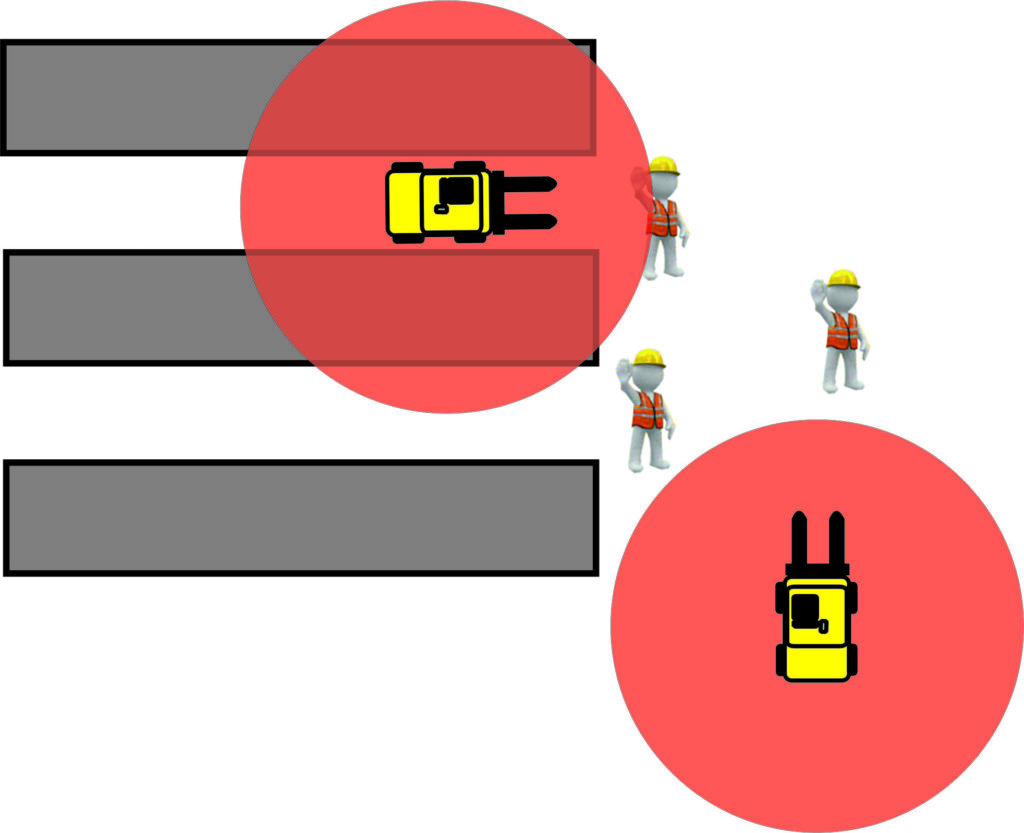

The pedestrian-vehicle anti-collision function is one of the most requested and appreciated features by our customers. In a dynamic work environment, where pedestrians share space with transport vehicles, safety is an essential topic. Tamarri Srl has developed an advanced solution to reduce the risks of accidents and guarantee a safer and more protected working environment.

How does it work

The pedestrian-vehicle anti-collision system is based on the use of wearable TAG (SS1001) by pedestrians and the central unit (SS1000) installed on forklifts. Here’s how it works in detail:

- Pedestrian detection: Every pedestrian, including forklift operators when not driving, wears an SS1001 TAG. These tags are equipped with motion sensors and rechargeable batteries, ensuring a long operating life and energy saving thanks to the standby mode activated after 10 minutes of immobility.

- Safety Areas: The system allows you to configure four detection areas around the forklift:

- Green zone: activated within a configurable distance of up to 95 meters. In this zone, the tag beeps every 2 seconds.

- Yellow zone: in this intermediate zone, the tag beep becomes more frequent, every second;

- Red zone: this is the maximum alarm zone. The tag emits a continuous beep every second accompanied by a vibration, indicating an imminent danger of collision.

- Silence area: to avoid false alarms when the forklift operator is outside the vehicle but close to it, it is possible to configure a silence area in which the tag does not trigger alarms on your forklift.

- Alarms and alerts: When a pedestrian enters one of the detection zones, the SS1000 System immediately activates audible and visual alarms on the forklift. At the same time, the tag worn by the pedestrian emits acoustic signals and, if necessary, vibrations, alerting the pedestrian to the danger.

- Personalized management of distances: detection distances can be customized via the SS1003 Configurator, taking into account the specific needs of the working environment. This allows the system to be adapted to the different speeds of the vehicles, the characteristics of the pavement and other critical variables.

Advantages of the pedestrian-vehicle anti-collision system

- Reduction of accidents: the implementation of the pedestrian-vehicle anti-collision system significantly reduces the risk of accidents between pedestrians and transport vehicles.

- Precise warnings: thanks to audible and visual alarms, both drivers and pedestrians are warned of danger in real time, allowing rapid and preventive reactions.

- Customization: the ability to configure detection distances and safety areas allows you to adapt the system to the specific needs of each work site.

- Energy efficiency: SS1001 TAGs are designed to last several days on a single charge and activate automatically with movement, ensuring efficiency and convenience.

- Reliability: the detection accuracy of 10 cm and the ability to penetrate obstacles make the system extremely reliable even in complex and crowded environments.

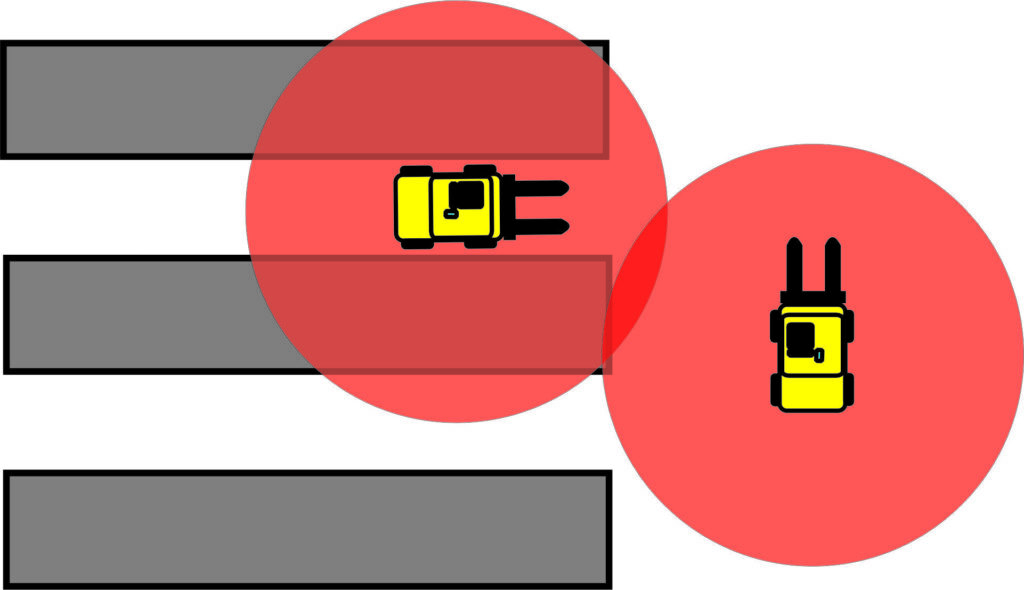

Machine-machine collision prevention: total protection for handling vehicles

In the logistics and handling sector, collisions between vehicles represent a significant risk, especially in areas of poor visibility or at intersections. Our Ultra Wide Band (UWB) technology helps mitigate these risks, ensuring a safer work environment and preventing costly damage to vehicles.

.

How does it work

The machine-machine collision avoidance system uses the SS1000 central unit installed on each handling vehicle. Here are the operational details:

- Vehicle detection: each vehicle is equipped with the SS1000 central unit, which acts as both a transmitter and receiver of UWB signals. When two vehicles equipped with the system approach within a configurable distance, the system automatically enters alarm mode.

- Alarms and warnings: when the configured safety distance is exceeded, the SS1000 System activates visual and audible alarms on the vehicles involved. Operators are immediately alerted to the presence of another vehicle nearby, allowing them to take preventative measures to avoid a collision.

- Automatic activation of alarms: the system can activate additional safety devices such as warning lights and buzzers, connected to the central unit via dedicated connectors. These devices increase the visibility of the danger and improve risk communication between vehicles.

- Customized configuration: the safety distance can be customized through the SS1003 Configurator. Users can adjust the parameters based on specific operational needs, taking into account the speed of the vehicles and the characteristics of the working environment.

Advantages of the machine-machine collision avoidance system

- Reduction of collision risks: the system significantly reduces the risk of collisions between trucks, especially in areas with poor visibility or at intersections.

- Timely alarms: visual and audible alarms immediately alert operators, allowing quick reactions to avoid accidents.

- Versatility and adaptability: the system is suitable for any type of handling vehicle and can be configured for different operating situations.

- Easy installation: the SS1000 central unit is simple to install and integrate into existing vehicles, without the need for complex additional devices.

- Accuracy and reliability: UWB technology guarantees a detection accuracy of 10 cm, ensuring that alarms are activated only when actually necessary, reducing false positives to a minimum.

Application scenarios

The Tamarri Srl machine-machine collision avoidance system is ideal for a wide range of applications, including:

- Warehouses: where vehicle movement is intense and visibility areas may be limited.

- Construction sites: where different types of vehicles operate in close proximity to each other, increasing the risk of collisions.

- Logistics areas: where coordination between vehicles is essential to maintain a safe and efficient workflow.

- Loading and unloading areas: where the presence of numerous vehicles makes accident prevention crucial.

Management of intersections and work areas: control and safety in critical areas

The management of intersections and work areas is essential to prevent accidents in particularly busy and high-risk areas, such as intersections and pedestrian crossings. The innovative UWB anti-collision solution ensures optimal control and increases safety in these critical areas.

How does it work

The intersection and work area management system utilizes the SS1000 central unit and SS1002 sensors to create a safe and monitored environment. Here’s how it works in detail:

- Slowdown sensors: the SS1002 sensors, constantly powered, are positioned in strategic points of intersections and work areas. These sensors never go into standby to ensure continuous and reliable monitoring.

- Create safety zones: The system defines safety zones around intersections and work areas. When a vehicle equipped with the SS1000 central unit enters these areas, the system activates visual and audible alarms, warning the operator to slow down and pay attention.

- Area configuration: using the SS1003 Configurator, it is possible to customize security areas based on the specific needs of the work environment. Configuration includes detection distance and alarm settings, allowing precise control adapted to different operating situations.

- Continuous monitoring: thanks to UWB Technology, the SS1002 sensors guarantee precise and reliable coverage, detecting the presence of vehicles and activating alarms in a timely manner. This allows you to effectively manage risk situations and prevent accidents.

Advantages of the intersection and work area management system

- Improved safety: the system significantly reduces the risk of accidents in high traffic areas and intersections, ensuring a safer working environment.

- Timely warnings: visual and audible alarms immediately alert operators, allowing them to take preventive measures.

- Adaptability and customisation: safety areas can be configured according to specific operational needs, ensuring precise control adapted to different situations.

- Constant monitoring: the SS1002 sensors, constantly powered, ensure continuous monitoring without interruptions, increasing system reliability.

- Ease of installation: the system is simple to install and integrate into existing vehicles and environments, without requiring complex modifications.

Application scenarios

The Tamarri Srl intersection and work area management system is ideal for a wide range of applications, including:

- Warehouses: where vehicle movement is intense and visibility areas may be limited.

- Construction sites: where different types of vehicles operate in close proximity to each other, increasing the risk of collisions.

- Logistics areas: where coordination between vehicles is essential to maintain a safe and efficient workflow.

- Loading and unloading areas: where the presence of numerous vehicles makes accident prevention crucial.

Advantages of the UWB Collision Avoidance System

- High precision: UWB technology guarantees a detection accuracy of 10 cm, drastically reducing the risk of accidents.

- Reliability: penetrates obstacles and has a low tendency to signal bounces, making the system reliable even in complex environments.

- Versatility: suitable for use in both open and closed spaces, such as warehouses, construction sites and production areas.

- Simplicity of installation: the system is easy to install on any type of vehicle, thanks to its intuitive design features.

System components

The system consists of different modular elements, which can be purchased individually based on the specific needs of the customer:

- SS1000 Forklift device: the heart of the system, which acts as both a transmitter and a receiver.

- SS1001 TAG Pedestrian: devices wearable by pedestrians, equipped with sound and vibration alarms.

- SS1002 Slowdown sensor: used to manage intersections and work areas.

- SS1003 Configurator: essential tool for configuring and customizing the system.

Tamarri Srl: innovation, safety and reliability

Tamarri Srl constantly innnovates the forklift safety sector, providing advanced solutions to reduce the risk of accidents and improve worker protection. Our UWB System represents a leap in quality in the management of safety at work, always keeping reliability and ease of use at the center.

Tamarri Srl is committed to providing innovative solutions that protect workers and improve operational efficiency. The integration of the UWB System into company processes not only reduces the risk of accidents, but helps create a safer and more productive working environment.