Automation and safety in warehouses are managed by various tools. For years, Tamarri has put safety at the center of its business, thanks to the safety first paradigm! Today we want to introduce you to a truly cutting-edge product: 2D LiDAR sensors (also 2D laser scanners) suitable for surface measurement and detection functions.

How the 2D laser scanner works

Based on the principle of light propagation time measurement, compact devices scan the surrounding environment and measure distances. Thanks to the integrated rotating mirror, a two-dimensional monitoring of protected areas is generated, which are individually definable.

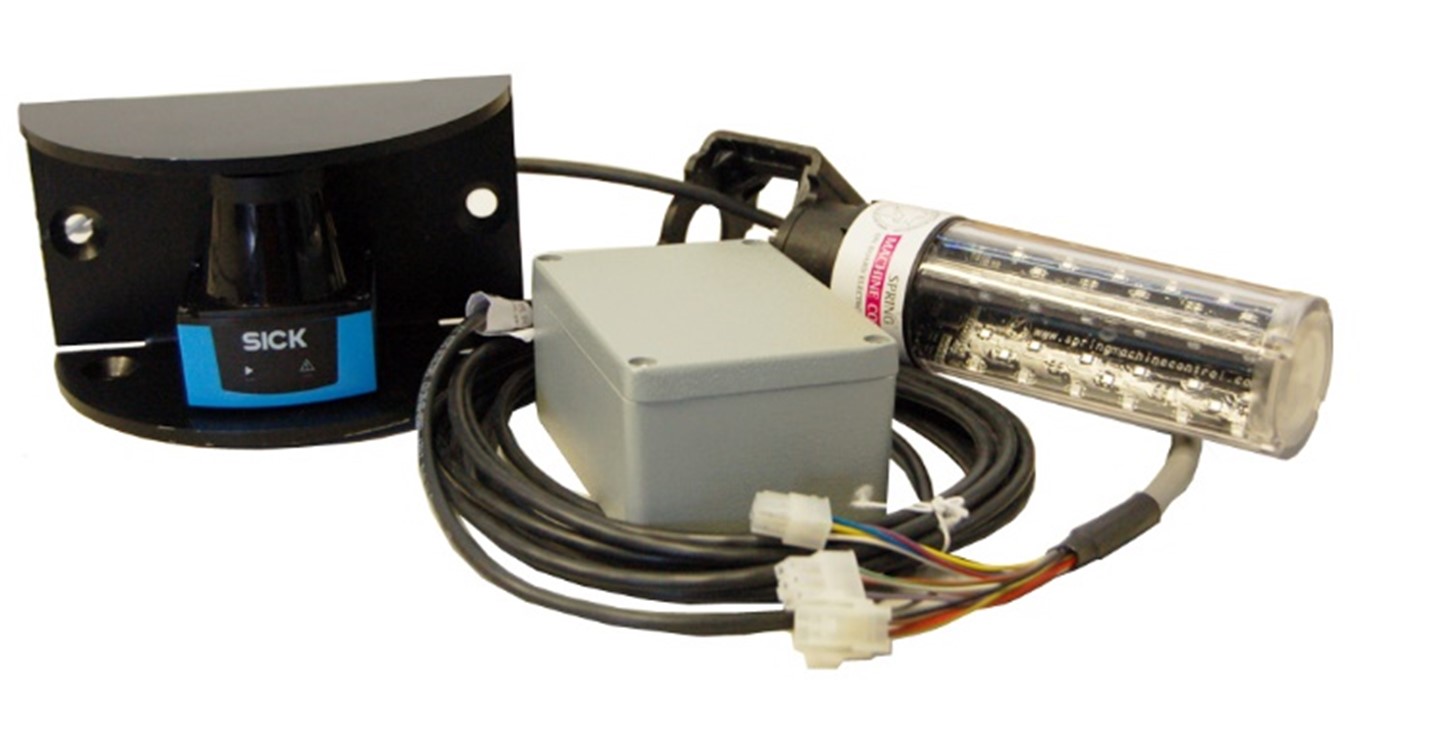

The new sensor-based, rear collision avoidance system of the latest generation is enclosed in a very strong 5mm-thick metal stand easy to install even on the ballast of the truck.

Our SS61K kit consists of:

– 2D LiDAR sensor with mounting bracket

– 12-24vDC relay box

– Led lamp with buzzer

– Connection cables

Regardless of the angle at which they are placed, SICK’s 2D LiDAR sensors always work reliably and accurately, both indoors and outdoors. For navigation, surveying or measurement, 2D LiDAR sensors provide reliable measurement data in numerous applications: from warehouses to manufacturing and from port areas to construction sites.

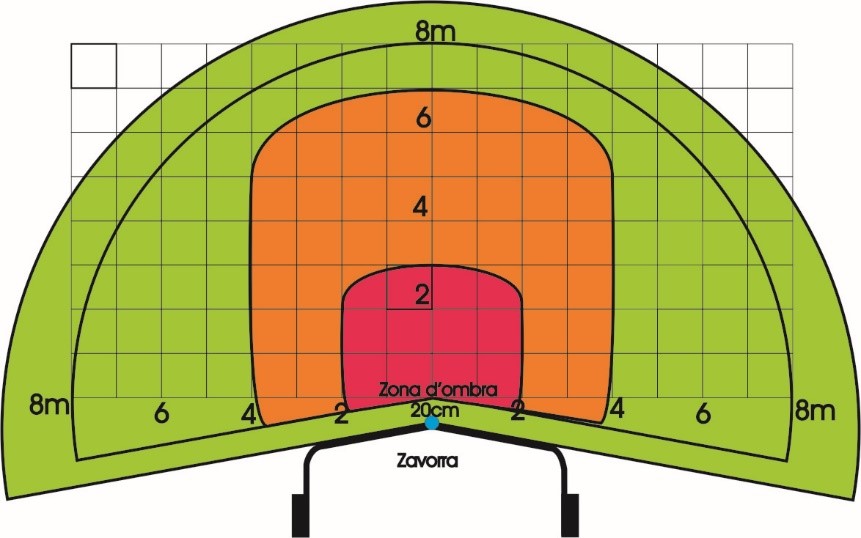

Two different intercept areas can be set, each managed by a separate digital output, adjustable in scan amplitude from 0 to 120°, in obstacle detection distance from 20/800cm.

The sensor performs a two-dimensional “2D” scan and detects both people and stationery or moving obstacles with an accuracy of 5 cm, with an almost immmediate responsiveness to the obstacle on the outputs. However, it is necessary to define the mounting position of the sensor on the vehicle, with special attention to ‘height, depending on the use needed by the customer.

Warehouse operation

The most common application of the sensor is on the rear ballast of the truck at about 40 cm height, so that the sensor is able to intercept even obstacles on the ground.

Settings of two different detection areas:

– Area 1, with 120° scan depth 6..7m first slowdown (orange area);

– Area 2, again scanning at 120° depth 2..3m second slowdown (green area).

The two digital outputs coming from the sensor are sent to the relay board ( 3 relays CO.NC.NA ) to which the supplied led lamp is connected, which transmits the danger status to the operator in the form of color and acoustic signal; in addition, it is possible to configure the slowing down of the vehicle.

– No obstacle, green light and no acoustic signal

– Obstacle in area 1, orange light with intermittent acoustic signal

– Obstacle in area 2, orange light with continuous acoustic signal

In some applications, the lamp is used as the only hazard warning, without intervening in the slowing down of the vehicle, making it easier and faster to apply the kit.

SICK safety laser scanners combine know-how and experience with excellent performance.

Tamars, automation and safety! 😉

This is how you can understand if there is room to use them even better to achieve maximum efficiency and therefore full customer satisfaction.

This is how you can understand if there is room to use them even better to achieve maximum efficiency and therefore full customer satisfaction.